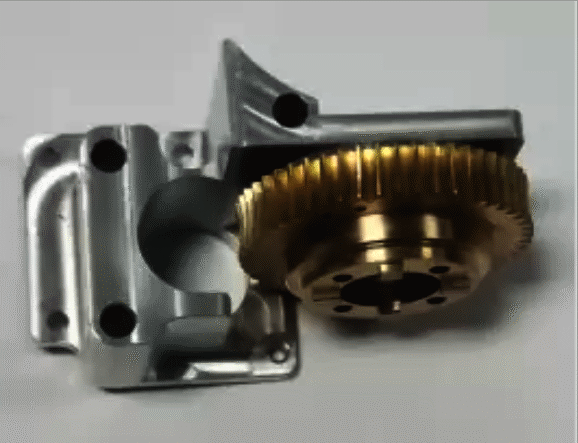

CNC Milling High-Precision CNC POM/ PA Machining Services With Phosphating Surface

CNC milling processing is suitable for precision and complex parts processing, periodically repeated production parts processing, multi-station, multi-process concentrated part processing. The main processing objects are box parts, complex curved parts, special-shaped parts and discs, and plate parts. As a professional CNC milling company, ETCN provides the best china CNC milling service.

CNC Milling High-Precision CNC POM/ PA Machining Services With Phosphating Surface Specifications :

| Price | Contact us |

| Brand Name | ETCN |

| Place of Origin | Shanghai |

| Min.Order Quantity | 100 |

| Payment Terms | T/T,L/C,D/P |

| Supply Ability | 3 days |

| Delivery Detail | 3days--7days |

| Packaging Details | Wooden case or wooden pellets depended on clients' require |

CNC Milling High-Precision CNC POM/ PA Machining Services With Phosphating Surface Detail Introduction :

CNC Milling Capabilities

The comprehensive processing ability is strong. After the workpiece is clamped at a time, more processing contents can be completed. The processing accuracy is high. The efficiency of batch workpieces with medium processing difficulty is 5-10 times that of ordinary equipment, especially it can complete much ordinary Processing that cannot be completed by the equipment is more suitable for single-piece processing with complex shapes and high precision requirements or for small and medium batches of multiple varieties. It concentrates the functions of milling, boring, drilling, tapping, and cutting threads on one device so that it has a variety of technological means. To provide you with a high standard of CNC Machining Services.

CNC Milling Material and Finishes

Machinery | 5 | |

Material | Alloys Steel | Bronze Alloys |

Aluminum Alloy | Stainless Steel | |

Copper | Carbon Steel | |

Brass | POM/PA | |

Features | Deburring | Drilling |

Tapping | Milling | |

Threading | Boring | |

Grinding | Knurling | |

Maximum Dimensions | 800mm*500mm*550mm | |

Milling Tolerance | ±0.005mm | |

Inspection Capabilities | CMM | Projector |

Imaging Measuring Instrument | Hardness | |

Metallographic Microscope | Non-destructive Equipment | |

Automatic Thread Inspection Equipment |

| |

Surface Finished | Zinc Plated | Sand Blasted |

Nickel Plated | Blacking | |

TD Coating | Phosphating | |

Dacromet | Zinc-Nickel Plating | |

Thread | UNF | UNC |

NPT | SAE | |

Metric | BSPP | |

BSPT | JIS | |

DIN | G | |

R | ZG | |

Certification | ISO9001-2008 | ISO/TS16949 |

Advantage of CNC Milling

CNC milling processing is suitable for precision and complex parts processing, periodically repeated production parts processing, multi-station, multi-process concentrated part processing. The main processing objects are box parts, complex curved parts, special-shaped parts and discs, and plate parts.

Telephone :+86 (21) 6140 3577

Telephone :+86 (21) 6140 3577 WhatsApp :+86 13916036822

WhatsApp :+86 13916036822 Email :

Email :