Our products are widely used in automation, optics, communication electronics, medical, new energy and other fields. The purpose of our company is excellent quality, reasonable price, and good service. We provide professional technical data support and reliable solutions to meet the customization needs of various processed products, with excellent quality and fast delivery.

CNC Machining Services Recommend Products

CNC Machining Services Video

Download Brochure

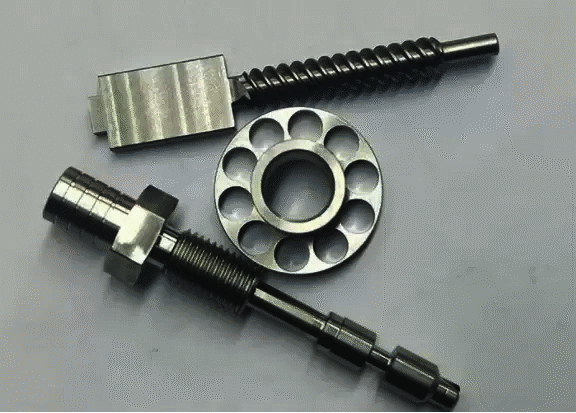

- Carbon Steel/ Stainless Steel CNC Machining Parts, CNC Lathe Turning Parts

- CNC Precision Turning Milling Stainless Steel Air Compressor Valve Plate Parts

- CNC Milling High-Precision CNC POM/ PA Machining Services With Phosphating Surface

- High Efficiency CNC Boring And Milling Machining Service Support OEM/ ODM

CNC Machining Services Detail Introduction

cnc machining services

We specialize in designing and producing high-precision metal parts and are a CNC machining service factory. Our products involve all kinds of metal processing, laser cutting, flame cutting, sheet metal, CNC machining, stamping, mold, and large welded structural parts. With our experienced workers and strict quality control, we can provide our customers with quality products at low prices.

We offer a full range of production services casting products from mold design and development to mold forming and post-processing as well as surface treatment. Our products are mainly used in the aerospace industry, lighting decoration, electrical appliances, auto parts, furniture parts, power tools, medical devices, intelligent automation equipment, etc.

For each part, depending on the expected production volume, we will ultimately choose the right manufacturing process to make the product cost-effective, acceptable quality, and fast delivery time. We all believe that only professionalism and integrity can bring our customers closer to us, and only with their trust and support can we go farther and stronger.

CNC machining process flow

Read the parts --- process analysis --- develop the process --- CNC programming --- program transmission

The main contents of the CNC machining process

1、Understand the technical requirements of the drawing, such as dimensional accuracy, form tolerance, surface roughness, material of the workpiece, hardness, processing performance and the number of workpieces, etc.

2, according to the requirements of the part drawings for process analysis, which includes the structure of the part process analysis, material and design accuracy reasonableness analysis, the general process steps, etc.

3, according to the process analysis to develop the process information needed for processing, such as processing process route, process requirements, tool trajectory, displacement, cutting amount and auxiliary functions, and fill in the processing process card and process card.

4, according to the part diagram and the development of the process content, and then in accordance with the CNC system used to specify the instruction code and program format for CNC programming.

5, will be prepared by the program through the transmission interface, input to the CNC machine tool CNC device, adjust the machine and call the program, you can process the parts in line with the requirements of the drawings.

More description

CNC machining service process is based on the original conditions such as the part drawing and process requirements, prepare the part CNC machining program, and input to the CNC machine tool's CNC system to control the relative motion of the tool and workpiece in the CNC machine tool, so as to complete the process of parts processing.

Our company performs very well in CNC machining services, with stable processing quality, high precision and can process complex surfaces. The series of products we produce are subject to strict quality inspection and are manufactured by a professional design team and an experienced manufacturing team, and the equipment used to produce all kinds of parts is very advanced.

The company has the same machine processing capacity as the castings, and the machine processing facilities are completely independent from the foundry, with an independent management team and a tailored business model. We have completed the transformation and upgrade to a deep processing manufacturer with expanded capacity and are committed to having capabilities other than casting, focusing on the development of high-end market end products.

We focus on every detail to make every part achievable, and our approach is to select the simplest, most cost effective manufacturing process and 100% quality assurance for our customers' projects. If you need, feel free to contact us, we can provide you with the best quality products and perfect service, your satisfaction is our pursuit.

Complete purchase guide for CNC machining services

With the progress of society, the development of CNC industry is getting better and better, CNC machining technology, CNC machining equipment, CNC machining services and other aspects have been significantly improved, take a look at this guide below, it will bring you great help.

1.What is CNC machining

CNC machining refers to a process method of parts processing on CNC machine tools, by the control system to issue instructions to make the tool for a variety of movements to meet the requirements, in the form of numbers and letters to indicate the shape and size of the workpiece and other technical requirements and processing process requirements for processing, it refers to the process of parts processing on CNC machine tools in general.

CNC machine tool processing and traditional machine tool processing process protocols are generally speaking the same, but also undergone significant changes. The use of digital information to control parts and tool displacement machining methods. It is to solve the variety of parts, small batch, complex shape, high precision and achieve efficient and automated processing of the effective way.

2.CNC machining process analysis

(1) size labeling to meet the characteristics of CNC machining: in CNC programming, all the points, lines, surface dimensions and positions are based on the programming origin.

(2) reliable positioning datum: in CNC machining, the processing process is often concentrated, positioning with the same datum is very important, so it is often necessary to set some auxiliary datum, or add some process tabs on the blank.

(3) unified geometric type or size: the shape of the part, the cavity is best to use a unified geometric type or size, so as to reduce the number of tool changes, the shape of the part as symmetrical as possible, easy to use the CNC machine tool mirror processing function to program.

(4) the conditions of geometric elements should be complete and accurate: in the preparation of the program, the programmer must fully grasp the parameters of the geometric elements that constitute the contour of the part and the relationship between the geometric elements, no matter which point is not clear programming can not be carried out.

3. CNC machining services processing principles

(1) the processing process, the processing of the previous process can not affect the positioning and clamping of the next process.

(2) follow the principle of first inside and then outside, that is, the processing of the internal cavity first, after the processing of the shape.

(3) With the same installation or use the same tool processing process, it is best to proceed consecutively to reduce the error caused by repositioning or tool change.

(4) In the same installation, the process that has less influence on the rigidity of the workpiece should be carried out first.

4.Benefits of cnc machining services

(1) process concentration: CNC machine tools generally with automatic tool changer, tool magazine, tool change process by the program control automatically, the process is more concentrated, can bring high economic benefits.

(2) a high degree of automation: CNC machine tools processing, no manual control of the tool, a high degree of automation, greatly improving efficiency, bringing obvious benefits.

(3) reduced manual labor intensity: in the processing, CNC workers most of the time are excluded from the processing, very time-saving and labor-saving, the processing process is compact, improving the labor productivity.

(4) stable product quality: CNC machine tool processing automation, eliminating the fatigue of workers on ordinary machine tools, carelessness, estimation and other human errors, to improve the consistency of the product.

(5) reduces the requirements of the operator: a short period of time is not easy to train a general machine tool senior workers, but can be trained without programming the CNC workers, and, CNC workers on CNC machine tools to process parts than ordinary workers on traditional machine tools to process parts of high accuracy, time to save.

5.How cnc machining services Works

The computer in the CNC control device through the input device in the form of digital and character code recorded information for a series of processing, and then through the servo system and programmable controller to the machine tool spindle and feed and other actuators to issue instructions, the main body of the machine tool in accordance with these instructions, and in the detection of feedback devices, the workpiece processing required for a variety of actions, such as tool movement relative to the workpiece trajectory, displacement and feed speed and other requirements to achieve automatic control, so as to complete the processing of the workpiece.

6.Industries using cnc machining services

(1) medical equipment industry: in the medical industry, many modern medical diagnosis, treatment equipment are used in CNC machining technology services, such as CT diagnostic instruments, full-body knife treatment machine and minimally invasive surgery robot based on visual guidance.

(2) automotive industry: engine, gearbox, crankshaft flexible processing line with CNC machine tools and high-speed machining centers, as well as welding, assembly, painting robots, plate laser welding machine and laser cutting machine, etc.

(3) aviation, shipping, power generation industry: processing propellers, engines, generators and turbine blade parts with high-speed five-coordinate machining center, heavy-duty turning and milling machining center, etc.

(4) information industry: from computers to networks, mobile communications, telemetry, remote control equipment, etc., all need to use ultra-precision technology, nanotechnology-based manufacturing equipment, such as chip manufacturing lead bonding machine, wafer bonding machine and lithography, etc., the control of these devices require the use of CNC technology.

(5) other industries: in the light industry, the use of multi-axis servo control of printing machinery, textile machinery, packaging machinery and woodworking machinery; in the building materials industry, for stone processing of CNC waterjet cutting machine; for glass processing of CNC glass carving machine; for Simmons processing of CNC line sewing machine and for garment processing of CNC embroidery machine, etc..

7.Types of cnc machining services in the Market

(1) cutting class: the method of removing material to change the shape of the workpiece, such as CNC turning, CNC milling, machining centers, engraving machines.

(2) Forming processing: direct change the shape of the workpiece with a mold, without producing iron chips, aluminum chips, such as CNC stamping, CNC spinning, etc.

(3) special processing: such as wire cutting, EDM, plasma cutting, etc.

8.cnc machining services Maintenance Process

In CNC machining services, the use of CNC machine tools should pay attention to a variety of issues, the operator should be familiar with the performance of CNC machine tools, to achieve skilled operation, but also to develop a civilized production of good working habits and rigorous work style, operation should pay attention to the following points.

(1) strictly comply with the safety operating procedures of CNC machine tools, without professional training shall not operate the machine tool without permission.

(2) strictly abide by the shift and handover system.

(3) to do a good job, good management of machine tools, with a strong sense of responsibility for the work.

(4) maintain a good clean environment around the CNC machine tools.

(5) Operators should wear good work clothes, work shoes, not wearing dangerous clothing.

9.How to Verify Quality of cnc machining services

(1) Material inspection: Check the material surface and rough dimensions.

(2) Mass production first inspection: to ensure the critical dimensions in mass production.

(3) Sample inspection: Check the quality before sending to the warehouse.

(4) Pre-shipment inspection: 100% inspection by QC assistant before shipment.

10.How much cnc machining services Cost

We are a physical factory, not a trading company, so our prices are very competitive. The price is the composition of the actual product quality price, the quality can guarantee a higher controllability than the trading company. The price is lower, at least by reducing the service fees of the trading company. We integrate all raw material requirements and purchase in large quantities from approved suppliers with reasonable prices and high quality.

11. About us

We specialize in CNC turning, CNC milling, CNC bending, laser cutting, stamping, grinding, wire cutting, casting and surface treatment. The company is equipped w th the most advanced high-speed CNC machine tools and measuring instruments. We are committed to provi ing the best service to our valued customers with excellent quality, competitive prices and reliable on-time delivery.

We focus on CNC machining. Focus on excellent crafts anship, absolute quality, cleanliness and delivery time. We are a united team of t lented and experienced engineers, mechanics and technical consultants. Committed to manufacturin precision machined parts and related issues of CNC Machining Services, including design, product costing, quality, assembly services, etc.

As a leading manufacturer of high-precision CNC machining parts. We have rich experience i production and service. CNC milling serves multipdeveloping, producing e industries such as medical, LED, electronics, telecommunications, automobiles, sensors, industrial applications, aerospace, and defense. We can provide customers with high-quality products and good service. You can contact us at any time if you have any needs.

12. Our advantages:

(1) Imported production equipment center

The processing equipment is imported from Germany and Japan high-precision four-axis and five-axis machining centers. Various supporting facilities are very complete, providing CNC machining, CNC lathe, and oxidation surface treatment.

(2) High-precision machining center

Combine its own powerful CNC machining, CNC turning and milling and other good processing capabilities. Provide a one-stop service of reliable high-tech service production for products in the industry.

(3) High-precision testing equipment

Efforts to meet the high requirements of customers' production one-stop service. With excellent product quality and professional quality inspectors, we are your safe choice.

(4) High-precision technical team

Surface treatment experience, advanced processing equipment, excellent product quality, professional quality inspectors, and professional technical team can provide you with a complete set of reliable services.

13. Perfect service system

(1) Follow up the processing progress of customers' products throughout the process. Let customers understand the production progress, rest assured and worry-free.

(2) Respond to customer feedback on product issues within 24 hours. Solve problems for customers in a timely manner.

(3) If the product is damaged due to our reasons, we will remake it unconditionally.

(4) The CNC control system can be adapted to stepper motors or servo motors. Provide customers with good cost-effective solutions.

(5) We will carry out quality inspections on the raw materials of the products. Ensure that it is qualified, and carry out necessary tests and inspections during the production process of the product.

Our CNC milling products are strictly controlled during the manufacturing process. The quality is guaranteed, and the CNC milling service performs very well in all aspects. Our employees have rich business experience, good language skills, and rich foundry or mechanical background. We can provide customers with good service. If you have a need in this regard, don't hesitate to contact us as soon as possible. We will serve you wholeheartedly.

14.CNC Cutting

A computer numerical control router is a type of cutting machine controlled by computer software. It typically mounts a hand-held router as its spindle. These machines can cut wood, composites, aluminium, steel, glass, foam, plastic, and other materials. CNC routers are designed to provide precise, high-quality results on a wide variety of materials. These routers are ideal for manufacturing precision parts, and can be used to make intricate shapes and sizes on a wide variety of surfaces.

CNC cutting uses a specialized computer that controls a CNC router to cut a piece of material. It can produce a number of shapes and sizes and is particularly useful for small-scale fabrications. The CNC router can produce complex designs and shapes and can be programmed to create intricate patterns. Because each customer has different tastes and needs, designers take these ideas into account when creating a CNC-controlled product. For more information, visit CNC cutting.

CNC cutters use a CNC router to cut out complex shapes. The computer controls the router's movements and allows the user to choose the most precise size. Different customers want different designs, and CNC cutters can make them. A typical CNC user will take the customer's ideas and incorporate them into a design that meets their specifications. The computer then uses these ideas to create a custom product. The entire process is automated and computer-controlled, making it the best choice for the majority of companies.

Telephone :+86 (21) 6140 3577

Telephone :+86 (21) 6140 3577 WhatsApp :+86 13916036822

WhatsApp :+86 13916036822 Email :

Email :