The Ultimate Guide to Faqs : Metal Machining Service Suppliers

If you are considering buying this service, you must have tons of queries in your mind. Here is a comprehensive guide that will help you choose the best company and supplier.

1. What Are the Benefits of Using a Metal Machining Company?

There are many benefits to using a metal machining company to get your work done. Your product will be made with the best materials, but you'll also have a skilled and knowledgeable staff doing the work for you. Here are just a few of the additional benefits of using a metal machining company:

Quality control. When you use a metal machining company, you can rest assured that each process step will be monitored carefully. This means that any imperfections in your product will be spotted early and corrected immediately.

Faster turnaround. You'll save money and time by not having to go back to the drawing board when something goes wrong with your project. Your metal machining company will make corrections or replacements on-site rather than sending your work back to you for corrections.

Better results. Metal machining is extremely precise, which means fewer errors in the end.

Professional results. You're working with people who know what they're doing, so you can be sure that your product will be exactly what you need it to be.

2. What is Included in Metal Machining Service?

The metal machining service is a delicate and complex process that requires a high level of precision. It will help achieve the desired result, which will avoid unnecessary expenses and reduce work time. This article will help you determine what is included in the metal machining service.

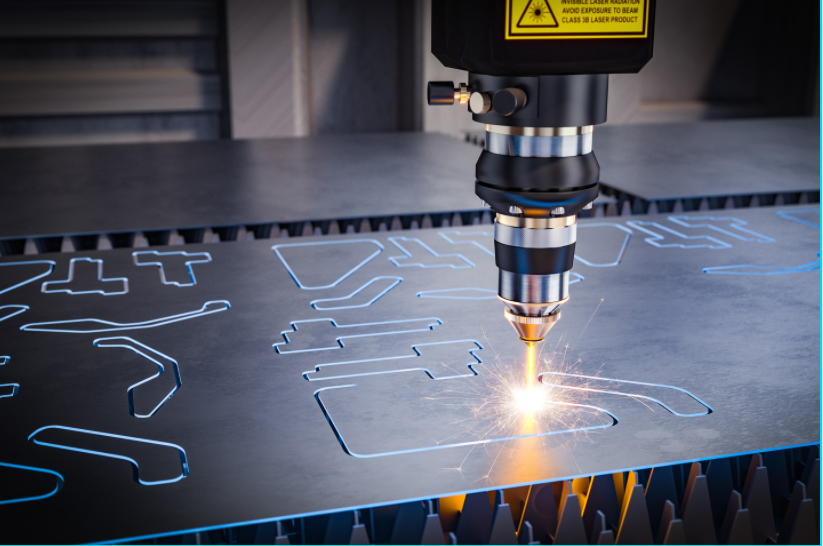

Metal machining is performed by cutting, stamping, drilling, grinding, and other methods. The required result may be different – from small parts to large structures. To obtain the desired result, it is necessary to use special equipment, knowledge, and experience of specialists.

The following operations are carried out during metal machining:

Cutting sheet material into small parts;

Designing made-to-order products;

Removing the excess material from details;

Grinding elements;

Making holes;

Turning lathing;

To ensure quality performance of all types of work, it is necessary to use special equipment, which can be very diverse. The choice depends on the specific task. In addition, specialists should have extensive experience with various materials and processing methods.

3. Who Can Use Metal Machining Services?

Machining is the process of cutting metal, including drilling and turning. It's used in the manufacturing and engineering industry to make parts for vehicles, machinery, and equipment.

The Manufacturing Process

Machining can be done in a workshop or factory setting. The parts are machined from raw materials with the help of machines and tools like lathes.

Precision Machining

Precision machining is a technique that uses high-end computer software to produce a product with an exact specification. It is usually used for products that need to be very high quality or where the tolerances are very tight. Precision machining produces products with very tight tolerances that other processes such as molding or casting cannot be achieved.

Who Can Use Metal Machining Services?

Any company that needs to produce precision metal parts can use metal machining services. This includes aerospace, automotive, and electronics companies, among others.

4. What is Metal Machining Service?

Machining is the processing of mechanical parts by various cutting tools to obtain the required shape and size. According to the machining methods, the common machining process can be divided into turning, milling, drilling, grinding, planing, broaching, and sawing. In addition, there are other special processing methods such as gear machining, thread machining, and heat treatment.

The main goal of machining is to make a very specific product with high accuracy and surface finish. The main tool used in machining is a chip removal tool. It can be made of high-speed steel or cemented carbide. It also has a variety of shapes such as square, round, triangular, and so on. Modern technical development has put forward higher requirements for machining equipment. Nowadays, numerical control machine tools have been widely used in production. They use digital information to control the operation of machine tools to improve work efficiency and reduce labor intensity.

5. What Types of Metals Can Be Machined?

Machining, or shaping metal and other materials using a high-speed cutter or drill, is an essential part of the manufacturing industry. The practice dates back to ancient times when artisans would use rudimentary tools to shape wood and stone into desired forms.

Metals are among the most common materials machined by manufacturers today. What types of metals can be machined?

Aluminum

Aluminum is widely used in manufacturing because it's relatively soft and easy to work with. It has good resistance to atmospheric corrosion and can be plated with zinc for enhanced durability.

Copper

Like aluminum, copper is also a soft metal that a machinist can easily work. However, copper can be difficult to machine at high speeds because it tends to break apart. Machine shops are often required to use special cutting fluids when working with copper and slower speeds and more powerful equipment than when machining other metals.

Steel

Steel is one of the most commonly used metals in manufacturing because it's strong enough to support heavy loads but flexible enough to be bent into various shapes. Steel is also extremely durable, making it ideal for use in many industries, including construction, automobiles, and machinery. Steel is typically alloyed with carbon or iron to increase.

6. How Should I Prepare My Design for Manufacturing?

Whether you're a startup or an established company, knowing what to expect from the manufacturing process can help you set up for success. Here are some common questions and answers to help you get your design ready for production.

What steps should I take before going to manufacturers with my idea?

Let's assume you have a product concept and need to figure out how to get it made. You'll need to decide if you want to hire a consultant or if you're comfortable taking on the task yourself. Then, start researching manufacturers that might be able to make your product. You can search online or attend trade shows like CES in Las Vegas or the International Home + Housewares Show in Chicago. You might find a manufacturer already doing something similar to what you have in mind.

What are some of the things I should know about manufacturing?

First, understand that most manufacturers don't do everything in-house — they may make their molds or have their injection machines, but they have suppliers for everything from screws and bolts to shrink wrap and tape. So, while they may be able to do most of the work on your project, they'll still need some additional parts and supplies from outside vendors. You should also be aware that some companies only provide labor.

By providing a set of metal machining service supplier faqs, we can help clients get to metal machining service suppliers quickly and easily. Such customers need to find metal machining service suppliers with the best experience in related technology.

Metal Machining Service Suppliers are easy to work with and offer many benefits.

recommend reading:

- Top 20 CNC Machining Services Companies in the world.

- The Ultimate Guide to Faqs : China Metal Machining

- The Ultimate Guide to Faqs : Metal Machining Service Suppliers

- The Ultimate Guide to Faqs: Stretch Forming Aluminum Sheet

- The Ultimate Guide to Faqs: China CNC Machining Company

- CNC Machining of ABS for Heavy Fabrication

Telephone :+86 (21) 6140 3577

Telephone :+86 (21) 6140 3577 WhatsApp :+86 13916036822

WhatsApp :+86 13916036822 Email :

Email :