Choosing a China Metal Parts Manufacturer

Choosing a China Metal Parts Manufacturer

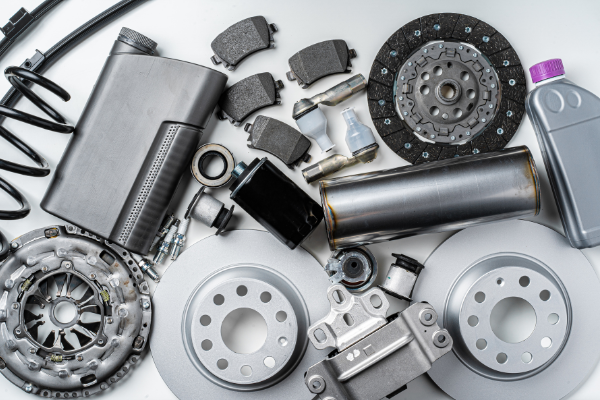

If you are looking for a china metal parts manufacturer, you are lucky! There are many options available. One such company is China ETCN. ETCN specializes in metal injection molding, sheet metal, stamping, and forging. The company also offers various services such as welding, metal surface treatment, and assembling components. Custom stamped metal parts are also available. Contact us today to find out more!

Custom stamped metal parts.

Several industries use custom-stamped metal parts. For example, the electrical industry makes extensive use of these parts, which are extremely durable and resistant to high temperatures. Appliances such as refrigerators, stoves, and dishwashers also require various components with high workability and durability. If you are looking for a manufacturer to manufacture custom stamped metal parts for your products, KDM Steel is the perfect place to start your search.

Choosing a manufacturer specializing in custom metal stamping from China can give you an edge in the competitive market. When sourcing metal stamping from China, you should know several things. First of all, make sure that your manufacturer uses state-of-the-art technology. Some of the best metal stamping manufacturers use CAD and 3D software packages to ensure precision design and manufacturing. Ask for samples to ensure quality.

The company has been operating since 1993 and boasts a 5000-square-meter production facility. ISO9001:2015 and TS/IATF 16949 certified, it offers various services, including CNC machining, fabrication, welding, and assembly. The company is also ISO-certified and has a manual available upon request. Moreover, the manufacturer can handle all production phases, from prototyping to final assembly.

Another important benefit of sourcing from China metal parts manufacturer is that the company employs professional project engineers, who communicate with the designing engineers and product delivery personnel on your behalf. Their quality management system is ISO 9001 and IATF16949-certified and their delivery time is exemplary. The company's quality assurance and project management systems have led to 98% on-time shipping of their products. These advantages make them an essential choice for custom-stamped metal parts.

Cost

Among the many advantages of sourcing metal parts from China, one is the cost. China has the largest metal manufacturing industry in the world, dealing with about one-fifth of the global manufacturing demand. Chinese manufacturers provide low-cost metal parts, making them the number one choice of most big companies. China's low labor cost and ample supply of raw materials are attractive reasons to outsource metal parts to China. Some of the main advantages of sourcing metal parts from China are the following.

A combination of factors is driving up steel prices in China. Large construction projects are causing Chinese companies to halt production, while analysts fear that smaller businesses may have to lay off workers. A rise in the production of electric vehicles is another reason for the spike in steel prices. Manufacturers need high-strength steel for these vehicles because it reduces weight and improves performance. In the past few months, electric vehicle production has soared.

Suppliers

Finding metal parts suppliers from China is a more complicated process than sourcing other products from other countries. Metal products are an investment that can make a significant dent in your funds. Quality is very important when you source metal products from China. In this article, we will go over a few factors to consider when choosing a supplier. After all, you'll be using their products for years to come.

A good starting point is to consider the region where you plan to find metal products from China. For instance, Sichuan is one of western China's most important steel-producing regions. Other regions for sourcing metal parts from China include Shandong and Xinjiang. Knowing which regions of China produce metal parts and components can make choosing a supplier easier and help you avoid being scammed.

When selecting a supplier, you need to determine how capable they are. While this is difficult, a website will give you an idea of its capacity and scope. A website will also list important information about the manufacturing equipment and quality inspection devices used to check for quality. The supplier must be capable of meeting your demand and quality standards. If in doubt, make contact with the supplier directly. If you find a supplier that meets your specifications, it's a good sign.

Forging - China manufacturers can handle any size order and any type of metal product. The factories in China are highly automated and have invested in R&D. With these new processes. You can expect a high-quality and low-cost metal product. You can also expect OEM or ODM services from a Chinese manufacturer. Some Chinese companies can even use Pro-E 3D CAD software to create custom mold designs.

Quality

The quality of metal parts manufactured in China is not always as good as that of Western counterparts. Depending on the purpose of the parts, metals may be harder to process than other materials, resulting in lower quality and greater cost. While the GB column indicates the standard used in China, this column does not always apply internationally. Steels of almost every grade are available in China. As a result, the quality of metal parts manufactured in China may not be up to standard for your business.

When choosing a metal stamping manufacturer, look for ISO 9001:2008 certification and state-of-the-art technology. CAD and 3D packages are desirable technology features. These advanced systems can ensure the precision design and manufacturing of custom metal stamping products. To ensure quality, ask for samples of their metal parts. Always request the manufacturer to provide you with a sample of the products you're considering. It is best to check the samples of metal stamping products before committing to a large purchase.

Location

If you require high-quality metal parts, you should consider a metal Parts factory in China. These manufacturers are experienced and skilled in manufacturing a wide range of parts for a variety of industries. Some specialize in machining and investment casting, while others produce parts specifically for the aerospace industry. Regardless of the location, these manufacturers have the same quality standards as American suppliers. They can manufacture parts from almost any type of steel and have a quality system that checks materials for faulty parts.

- Top 20 CNC Machining Services Companies in the world.

- The Ultimate Guide to Faqs : China Metal Machining

- The Ultimate Guide to Faqs : Metal Machining Service Suppliers

- The Ultimate Guide to Faqs: Stretch Forming Aluminum Sheet

- The Ultimate Guide to Faqs: China CNC Machining Company

- CNC Machining of ABS for Heavy Fabrication

Telephone :+86 (21) 6140 3577

Telephone :+86 (21) 6140 3577 WhatsApp :+86 13916036822

WhatsApp :+86 13916036822 Email :

Email :